The production of lithium-ion batteries for electric vehicles (EVs) relies on a limited supply of critical minerals like lithium, cobalt, and nickel. With EV demand surging—approximately 17 million units sold in 2024 and projections of 20 million for 2025—properly utilizing and recycling EV batteries is crucial. Simply discarding batteries at the end of their vehicle life would waste valuable materials needed for future battery production, especially as mineral demand rises due to global policies shifting away from fossil fuels.

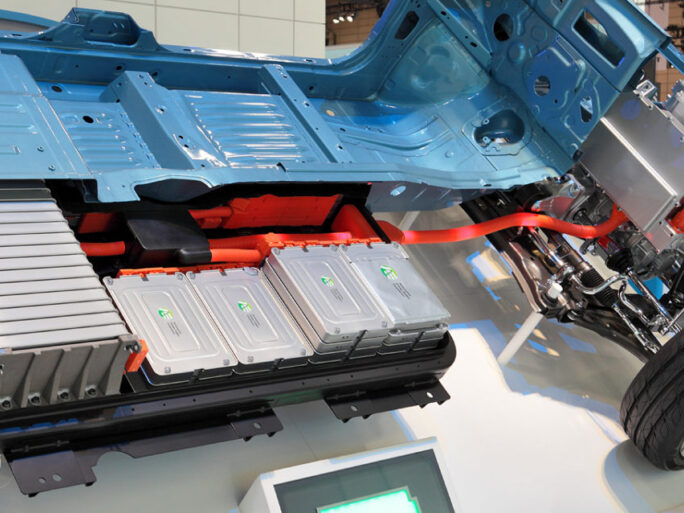

EV batteries often retain significant energy capacity even after their use in vehicles ends. Many can last 12–15 years, and some up to 40% longer, making them suitable for repurposing. Depending on their state of health, used batteries can be reused in smaller vehicles, refurbished, or redirected to other energy applications. However, assessing battery condition is difficult without detailed performance data, and degraded batteries pose fire risks, reinforcing the need for better data collection and handling.

Recycling is an increasingly viable solution. EV batteries can be shredded into “black mass,” which contains critical minerals that can be extracted and reused in new batteries. This process, though complex and costly, is becoming more common as manufacturers recognize the need to reduce dependence on finite mineral resources and the environmental toll of new mining. Recovered minerals help ease strain on a supply chain dominated by geopolitically sensitive regions like China, Indonesia, and the Democratic Republic of Congo.

Governments and private companies worldwide are investing in recycling initiatives. The U.S. Inflation Reduction Act has supported firms like Li-Cycle, which operates in North America and Europe. In the U.K., companies like Altilium are also expanding operations. According to European estimates, recycled materials from old batteries and factory scrap could meet a significant portion of mineral demand by 2030, potentially supporting production of millions of EVs. However, scaling up globally will require investment, skilled labor, and policy support to make recycling a cornerstone of a sustainable EV future.